Wooden worktop treatment: How to care for wooden kitchen worktops – prepping, cleaning and oiling

How to care for wooden kitchen worktops – prepping, cleaning and oiling

Ideal Home Newsletter

The Home Of Great Ideas For More Than 100 Years

Thank you for signing up to . You will receive a verification email shortly.

There was a problem. Please refresh the page and try again.

By submitting your information you agree to the Terms & Conditions and Privacy Policy and are aged 16 or over.

Wooden kitchen worktops are one of the most popular choices when it comes to kitchen surfaces. Wood is a traditional favourite thanks to its natural warmth and the character that comes as it ages. Hardwood materials are preferable over ‘soft’ woods due to strength and durability. Popular choices of hardwood include oak, walnut and iroko.

Wooden worktop ideas do need a certain amount of upkeep to preserve the surface, protecting it against the wear and tear of busy kitchen life. If your wooden worktops are varnished or lacquered, consider sanding and oiling them to get the best finish. Oiled wood not only has a richer, more natural patina, but the oil also helps to seal the surface, making it more durable and protected.

How to care for wooden kitchen worktops

(Image credit: Future PLC/ Rachèl Reeve)

1. Do the water test

Test oiled worktops to see if they need re-oiling by dripping water onto their surface. If the water forms a bead, it’s fine. If the water sits flat on the surface, you should re-oil as soon as possible.

‘In the first few weeks of use, special care must be taken to prevent the worktops becoming stained before they have built up sufficient oil protection’ says Phil House, Senior Wood Buyer at Worktops Express . ‘In particular water must not be allowed to lie on the surface. When the surface has a sheen, and water ‘beads’ or forms into droplets, you can tell that the worktop is in good condition.’

2. Sand and prep the surface

Use a hand-held electric sander to resurface the wood and remove any varnish, or simply to refresh previously oiled worktops.

‘Prior to placing the worktops in situ’ it is important that you oil ALL the edges and faces at least three times with Danish Oil’ advises Phil House. ‘Wipe away any surplus oil 15 minutes after application, and allow 6 hours between coats.’

(Image credit: Future PLC/ Claudia Dulak)

3. Oiling wooden worktops

Use linseed or Danish oil (available from DIY stores) and a lint-free cloth – microfibre works well. Pour a little oil directly onto the worktop and, using the cloth, spread it over the surface until you have a very thin and even layer. Keep going until you’ve covered all your worktop, then apply another coat.

‘To maintain the fine quality of your solid wood worktop, be sure to oil regularly’ advises the Phil House at Worktops Express. ‘Wood is a natural material and a proper course of oil treatment is essential to ensure a long and trouble-free life.

‘When the surface is dull and droplets don’t form, you need to re-oil the worktop. Ideally, you should re-oil the surface before it quite gets to that stage. New worktops will require treating frequently to build up their protection. However, as the protective layer builds up they will gradually require oiling less often.’

‘The environment in which it is fitted and the amount of wear and tear a surface receives will affect how often a worktop needs oiling. However, we would recommend regular re-oiling at least every three months.’

4. Leave it to dry

The oil will take a few hours to dry the first time you apply it, but up to eight or more hours for subsequent coats. Adding several thin coats is far more effective than just one thick coat – you can’t over-oil a wooden surface.

5. Cleaning wooden worktops

Try the water bead test once again and, if required, repeat the oiling process. If your worktops are brand new, it’s advisable to oil them at least twice over (preferably before fitting), including the edges and underneath, where they might be seen from certain angles.

‘Wipe worktops down regularly with a damp (not wet), lint-free cloth, warm water and a small amount of soap’ advises Phil House at Worktop Express. We do not recommend using multi-purpose cleaning products which contain chemicals as this may damage the worktops. Please also avoid the use of scouring pads.

(Image credit: Future PLC/ David Parmiter)

6. Protect wooden worktops from heat

To prevent your worktop getting stained or damaged, use trivets or glass surface protectors under hot pans so they don’t scorch the wood. Always use a chopping board to avoid damage and take care with pigmented spices, such as turmeric, which can stain the surface.

7. Keep sink areas dry

Try to keep the area around your sink dry, or the wood will begin to blacken and rot. Re-oil surfaces every three months. Take care with linseed or Danish oil as soaked rags can burst into flames as they dry.

Always choose a sustainable hardwood, preferably from an FSC (Forest Stewardship Council) accredited source.

How to Treat Real Wood Worktop Surfaces: A Nutshell Guide

It is hard to beat the unmistakable beauty of solid wood worktops. They radiate a natural beauty that cannot be equalled by other worktop materials. This material’s aesthetic is only enhanced by coating in a suitable protective treatment – either oil or lacquering. In this guide, we look at the different coatings available to treat real wood, and which will best suit your worktops.

Oiled Worktops

We recommend Danish oil as the best treatment to finish a worktop, as it will bring out the natural lustre of the wood whilst offering excellent protection.

As standard, all DIY worktops from Worktop Express® are provided unfinished, but if you choose to make use of our fabrication service, your worktops will have been sanded to an incredibly smooth finish and coated with commercial-grade HABiol oil on the top, bottom and edges of your worktop.

If you choose to purchase worktops without any fabrication or finish, then you will need to apply the oil yourself before installation, and regularly thereafter.

All worktops are supplied pre-sanded, but you may want to perform additional sanding to the worktop for a smooth 120 grit finish (read our ’How to Sand Solid Wood Worktops’ Nutshell Guide for more information).

We recommend using Rustins Danish Oil for all worktop oiling and aftercare. We advise applying at least two – three coats on the top and bottom of the worktop, 4 coats on the edges and up to 6 coats on the end grain. You will need to leave up to 8 hours between coats for the oil to be fully absorbed into the surface.

If regularly maintained, oiled worktops will look good for many years with a water-resistant finish. It is suggested that you regularly re-apply oil to the worktop during the first 6 weeks after worktop installation. After this period, you should then re-oil your worktop every 3 months to ensure the surface remains resilient and hydrophobic. To find out more about keeping worktops clean, read our How to Clean Wooden Worktops Nutshell Guide.

Danish oil is a mixture of polymerised linseed oil, varnish and drying agents, which combines to create a very hard-wearing and water-resistant finish.

Did you know we can pre-oil wooden worktops before delivery? Find out more on our Bespoke Cutting Service page, or visit our Online Bespoke Worktop Tool to order online. Our pre-oiling service starts at just £10 / metre or £9 per metre if ordered via the Online Bespoke Worktop Tool, with a 5 day lead time.

As an alternative finish, worktops can be lacquered for a hard-wearing finish. Keep reading to find out more.

Alternative finishes

Tung Oil: This product is formed from the pressed oil collected from the nut of the tung tree. It is a penetrating oil that has a wide variety of uses as a hard-wearing finish, curing to a satin look that sometimes adds a golden tint.

Sometimes – because of the nut content – tung oil can cause allergies, and so it is not entirely food safe. This is a primary factor in our choice not to use this kind of product on our wood worktops.

Linseed Oil: Otherwise known as flaxseed oil, this product is created by pressing the seeds of the flax plant, and is used both as a wood finishing products, and as a nutritional supplement, due to its sources of omega-3 fatty acids. It is a penetrative oil that on its own does not cover the surface like a varnish or Danish Oil.

We choose not to use Linseed-only oils because sometimes they can retain a sticky quality and take a long time to permanently dry. This oil type also does not harden particularly well, so is not a hard-wearing protective product that would suit wooden worktops. Lastly, it can also encourage mildew growth, meaning worktops would require more regular maintenance.

Wax: There are a variety of wood waxes available, but when referring to waxes suitable for worktops, it is often a hard wax oil that is being referred to. Wax does not provide a finish that is as hard-wearing as oil or lacquer, and creates a matt surface that requires regular polishing to buff into a more attractive sheen.

Want to see what oiled worktops look like before placing your order? Take advantage of our worktop sample service, or visit one of the Worktop Express kitchen showrooms to take a closer look at some of the timbers in our collection. All solid wood worktops on display in our showrooms have been treated with Rustins Danish Oil.

Wooden Worktops

Shop Wooden Worktops

Please note: this guide was originally posted on January 28th 2015, and was updated on 11th January 2018 to include additional information.

Filed under: Wooden Worktops by Worktop Express Admin on Thursday, January 11th, 2018

5 Comments »

How to Treat Wooden Worktops

For this DIY guide we look at how to treat wooden worktops. We run you through the steps of treating wooden worktops and how to oil worktops correctly to ensure that they last. Also included are tips repairing, resanding and restoring wooden worktops.

Oiling Treatment, Care and Maintenance of Hardwood Worktops

At Diydoctor we have received many questions asking which varnish should be used to re-vamp or repair a wooden kitchen worktop…The answer is NONE!

Timber worktops should be prepared without any application that is likely to chip or crack as if damaged they will harbour germs and become extremely unhygienic in no time and to these ends, in this project we will deal with how to oil worktops and kitchen work surfaces.

Oiling a Hardwood Kitchen Worktop

Hardwood worktops must be thoroughly treated with at least three coats of protective wood oil, to all sides (including the underside), prior to installation. It is also beneficial to apply as many coats as possible to the end-grain of the worktops as this is the area which will absorb the most moisture. An extra three to four coats should also be applied around tapholes, sink cutouts and areas of heavy use or exposure.

Oils are best applied by using a lint-free cloth rather than a brush.

Treated hardwood kitchen worktop

When applying the oil yourself, it is best to apply several thin coats rather than one thick application. Always work the oil into the worktop in the direction of the wood grain for best results.

After applying the first coat, you will probably notice that some areas are wet and others dry. This is because the wood will absorb the oil at different degrees in different areas. Wait for 15minutes and then run the cloth over the entire surface again to ensure an even spread. Do not allow large pools of oil to dry on the surface.

Apply the second and third coats in the same manner, allowing ½ hour – 1hour for drying time in between coats. If the surface feels slightly rough in certain areas, or if you wish to develop a smoother surface, then we recommend that you apply a further coat of oil using either a green nylon scouring sponge or wire wool.

Worktops can be finely sanded between coats using sandpaper between 120 grit and 180 grit.

However, you should never use sandpaper finer than 180 grit as it will sand the surface far too fine to allow future applications of oil from penetrating the surface correctly.

Aftercare and Maintenance of an Oiled Worktop

Ongoing care and oiling of the timber brings out and enhances its appearance as well as protecting the wood surfaces from wear and tear.

Your new worktop should be treated with oil every week for the first six weeks, and at least once every three months thereafter. If you think your worktop needs oiling more regularly then feel free to apply as often as you like – you cannot overdo it. This simple procedure will maintain the colour and lustre of your hardwood worktop and keep it looking as good as new. Just remember to always apply thin layers using a lint-free cloth and remove any excess oil after 10-15mins.

If a worktop is fitted over a Belfast type sink, oil should be applied monthly or whenever beading of water no longer occurs on the worktop surface.

Water spills and other liquids should always be mopped up immediately to prevent stains to the surface – especially during the first few weeks of installation. We advise keeping a tea towel handy solely for this purpose.

Worktops should be cleaned regularly using washing-up liquid and warm (not hot) water. Apply the water sparingly and wipe dry afterwards – water should never be left to stand on wooden surfaces for long periods.

Some Do’s and Don’ts

- Never use multi-purpose cleaning products that contain chemical cleaning agents and especially avoid scouring powders. A green nylon scouring sponge can be used for cleaning purposes but the area may require re-oiling afterwards

- Always use a chopping board for food preparation – cutting directly onto the worktop will damage the surface

- Hot pans, rough-bottomed objects and wet items should not be placed directly onto a wooden work surface – always use granite inserts, hot-rods, trivets, pan stands or heat-resistant mats to protect the worktop from scorch marks.

Direct contact from iron, steel or copper vessels can also stain the timber surfaces and should therefore be avoided

Renovating or Repairing Damaged Wooden Worktops

If your worktop is damaged, or very badly in need of renovation, it can be sanded down with some fine sandpaper (no finer than 180 grit).

For best results, slightly dampen the surface before sanding.

For larger, more extensive damage/dents etc, coarser paper can be used but then graded down to fine for the final sanding (again, no finer than 180 grit). The oil is then applied as above.

Worktop oil is generally a natural product made from various vegetable oils, which, mostly, are solvent, free.

Oils Used for Worktop Treatment

The oils that can be used to treat wooden worktops include:

- Danish Oil: Mixture of various oils such as Tung and Linseed. Danish oil provides great protection is by far the easiest oil to apply

- Tung Oil: Tung is a tree, found in China, parts of Africa and in some South American Countries.

Tung Oil provides excellent protection but is more difficult to apply and requires a much greater drying time

- Linseed Oil: Extracted from the seeds of the flax plant by steaming and crushing them. Raw linseed oil can be boiled to make the drying process faster. Linseed oil usually requires more applications than other oils as it dries out far quicker

- Teak Oil: Mixture of natural oils from vegetable products

Remember never apply varnish or paint to a surface that may be used to prepare food and always use a chopping board on wooden worktops. Food poisoning is not nice!

All project content written and produced by Mike Edwards, founder of DIY Doctor and industry expert in building technology.

How to oil wooden kitchen worktops so they look as good as new

When you buy a kitchen with beautifully chunky wooden worktops, the upkeep is unlikely to be a big priority. You’re redesigning your home and they look great, but they do also take a bit of looking after.

Over time, wooden worktops can fade and become marked, so it’s important to treat them every so often.

ADVERTISEMENT

How can I tell if my kitchen worktop needs re-oiling?

Most experts will tell you to re-oil worktops every three to four months, but to know for sure, Toolstation recommend dripping water onto the worktop surface. If the water forms a bead, it doesn’t need re-oiling, but if it sits flat on the surface, your worktop needs some TLC.

How to oil a wooden kitchen worktop in three steps

Step 1: Sanding

Use sandpaper (start with a courser grade sandpaper, then go over it with a finer grade, for example, 120 grit followed by 180, or 180 followed by 240 – available from all hardware stores) to smooth over all of your wooden worktops.

Sanding is a bit tedious and it will take a while, but on the plus side, it will lift off any stains or marks that are starting to set in. Focus on any discolouration around the sink area, as this can be harder to get rid of.

Make sure you clean off all the dust thoroughly once you’ve finished.

Step 2: Oiling

View this post on Instagram

A post shared by Natalie (@our_faversham_home)

Once you’ve done your prep, all you need to do is apply your oil. There are lots on the market, but try Rustin’s Worktop Oil – a water-borne blend of natural plant oils, suitable for all types of timber, quick-drying and water-resistant.

Rustins 500ml Quick Dry Worktop Oil by Rustins

- Rustins 500ml Quick Dry Worktop Oil

- 500ml

Last update on 2022-09-21 / Affiliate links / Images from Amazon Product Advertising API

To start, pour a little oil onto the worktop and, using a lint-free cloth, spread it over the surface until you have a very thin and even layer. You need to repeat this until you’ve covered the worktop, then apply another coat.

After applying, be careful not to leave any of the oil on the surface, as it could show up white and stand proud.

After the first coat, leave the oil to dry for a few hours (potentially more, depending on your brand of oil – always read the instructions) and then re-apply up to eight coats. Adding several thin coats is more effective than one thick layer, which can dry sticky or shiny.

Step 3: The re-test

com/p/CHpIu-Vn5zP/?utm_source=ig_embed&utm_campaign=loading” data-instgrm-version=”13″>

View this post on Instagram

A post shared by Emma Cox (@colyer.cox.abode)

Once dried, try dripping water on the surface again, and if the water doesn’t form a bead, repeat the oiling process.

3 of the best worktop savers

Now you’ve got gorgeously pristine worktops again, always use a heat protector or chopping board to keep it looking good.

(PA)

1. Joseph Joseph Stretch Silicone Pot Stan

Joseph Joseph 70033 Stretch Silicone Pot Stand – Black

- Expandable silicone pot stand

- Size can be adjusted to provide enough space for more than one pan or dish

- Made from high quality silicone nylon composite, heat resistant up to 220°C/428°F

Last update on 2022-09-21 / Affiliate links / Images from Amazon Product Advertising API

(Homesense/PA)

2.

(Lakeland/PA)

3. Beech Chopping Block, £21.99, Lakeland

Best-selling kitchen worktop oil

Stuck for inspiration? Check out our list of best-selling Amazon products!

Bestseller No. 1

Rustins Worktop Oil 500ml

- QUICK DRY WORK SURFACE TREATMENT

- PROTECTS ALL TYPES OF TIMBER

- LOW ODOUR, FOOD SAFE, DURABLE WATER RESISTANT NATURAL FINISH

Bestseller No. 2

WOCA Worktop Oil All You Need for The Maintenance of Kitchen Worktop or Furniture. This Danish Oil…

- Food Safe wood oil: Food contact approved ideal for kitchen worktops, kitchen furniture and work desk.

- All-Round protection against stains: Protect your wood against food stains, dirt and more.

- Perfect finish: Our wooden worktop oil penetrates deep into all types of wooden worktops and furniture.

Bestseller No. 3

Osmo Top Oil 3058 Kitchen Worktops- 0.5ltr x 2 tin Deal

- Osmo Top oil 3058

- Hardwax Oil by Osmo

- Satin Matt 3058

SaleBestseller No. 4

WOCA Worktop Oil kit (Natural) All you need for the maintenance of Kitchen Worktop or Furniture….

- Food Safe wood oil: Food contact approved ideal for kitchen worktops, worktable and work desk.

- All-Round Protection against wood stain: Protect your wood against food stains, dirt and more.

- Perfect Finish – Our wooden worktop oil penetrates deep into all types of wooden worktops and furniture.

Bestseller No. 5

Ronseal ABWO500 500ml Anti-Bacterial Worktop Oil

- Slow release silver guard barrier kills E Coli and MRSA

- Ideal for use in food preparation areas

- Nourishes and protects wood restoring lost oils

Last update on 2022-09-21 / Affiliate links / Images from Amazon Product Advertising API

You may be interested in…

This article may include affiliate links to products and services where we may receive a small fee to support the running of this site if you make a purchase or is a sponsored article from one of our select editorial partners providing valuable advice and information to our readers.

ADVERTISEMENT

A Comprehensive Comparison of All Wood Worktop Oils

How to choose the Best Wood Worktop Oil?

With the lack of sufficient protection, the beauty of the wooden worktops can easily fade away to become a disastrous kitchen surface. Although there is a myriad of wood worktop oils to choose from, not all of them can provide the utmost protection and longevity to the timber while also ensuring safety against food and beverage spillages. So how do we choose the best wooden surface Oil?

Here are is a comprehensive comparison of all solid wood worktop oils often recommended for treatment of timber products:

1. Olive Oil – the most ancient method!

Olive Oil is most commonly used in the treatment of wooden surfaces, more specifically wooden chopping boards. Although it has the ability to highlight the natural colors of the timber, when it comes to wooden worktops it remains insufficient in providing the sufficient protection.

Pros:

- Highlights the natural color and grain structure of the wooden worktop.

- Provides some protection against moisture and water, ideal for chopping boards, but it is still recommend to avoid high humidity

Cons:

- Insufficient moisture protection in the long term.

- Always wet on touch, so it can be uncomfortable to work with.

- Facilitates bacteria growth due to the humidity, it is vital to do a routine clean up at this point.

2. Linseed Oil – The main ingredient found in all most popular Oils!

Pure linseed oil can penetrate the timber worktop better than any other natural oil hence it is quite suitable in the treatment of hardwood worktops.

Pros:

- Penetrates the timber effectively

- Once it penetrates the pores, it seals them and protects the worktop from interacting with the moisture in the air and hence buckling up.

- Provides a suitable protection against water and moisture once enough layers have been stacked up.

Cons:

- Long Drying Time.

- Requires multiple coatings to build up the protective barrier (Note: this is rather easy and pleasant activity).

- Requires reoiling and maintenance on a regular basis. The wooden worktop will need to be re-oiled every 2-3 months – This can be even more if the “activity” that is taking place on the kitchen worktop is high.

3. Danish Oil – The most popular Choice

As mentioned before, linseed oil is suitable natural oil that is used as an ingredient for many other related products. Danish Oil is one of them – it is a mixture of polymerized linseed oil, varnish and drying agents, which combine to achieve a hard-wearing and water-resistant finish for wooden worktops. Danish oil is one of the most popular choices when it comes to oiling wooden worktops. Overall, it is an improved version of the Linseed Oil, as it also contains varnish and different drying agents, which help for a more hard-wearing surface and shorter drying times.

Pros:

- It penetrates the timber and the pores

- It seals the pores and protects the worktop from interacting with the moisture in the air and hence from buckling up.

- Provides a suitable protection against water and moisture once enough layers have been stacked up.

- Creates a hard-wearing surface

Cons:

- Multiple Layers need to be stacked to create a sufficient and strong protective barrier.

- Regular Maintenance and reoiling is needed -once every 3 months – it can be more depending on the activity that takes place in the kitchen – the wear and tear effect. To find out when the wooden worktops needs re-oiling, check out our guide When should you Re-Oil your Wooden Worktop?

- The surface can become sticky and unpleasant if thick coats are applied.

4. Teak Oil – Natural and glossy

Contrary to its name, teak oil in fact does not actually contain any oils or reminiscent of the teak tree. Many products are referred to as “teak oil” because they are marketed for use on teak and other similar timbers. Teak oils’ composition may vary but it is most often based upon a mixture of linseed oil, varnish, and mineral spirits. Many types of teak oil provide a good protective barrier for wooden worktops, but will often create a glossy sheet that – in our opinion – does not accentuate the beauty of hardwood timber worktop and looks artificial.

Pros:

- Forms a durable and strong protective barrier

- Penetrates the timber and its pores and hence seals them to provide additional protection against moisture

Cons:

- Creates a glossy surface which can become inconsistent as the wooden worktop wears and tears on certain areas.

- The Glossy Surface doesn’t accentuate the beauty of the hardwood, on the contrary makes the wooden worktop look artificial and unnatural.

- Requires regular maintenance and re-oiling.

5. Osmo Oil – Our Favorite! ❤️

Osmo Top Oil is a hard-wearing treatment specially formulated to protect your wooden kitchen worktop surface with a semi-matt appeal. Its highly hardwearing oil which has a natural microporous natural hardwax-oil wood finish. It is extremely moisture and water repelling and dirt resistant. The finish is resistant against wine, beer, cola, coffee, tea, fruit juices, milk, water and food particles. These types of liquid spillages will tightly bead on the surface without leaving any marks and can be simply cleaned by wiping with a cloth.

Osmo Top Oil requires minimal preparation before application. The product can easily be applied late at night, left to dry and will be ready to use the following morning. With an attractive luster, this product is available in clear satin, clear matt, acacia and natural tones.

Pros:

- Extremely tough and hard-wearing seal which protects against aggressive stains such as wine, fruit juices and etc.

- Seals the wooden worktop whilst allowing it to breath

- Easy to apply

- Only 3 Coats needed to form the perfect protective barrier.

- Food safe

- Needs minimal maintenance and re-oiling only once a year (the time period might vary depending on the wear-and-tear effect on the kitchen wooden worktop.

Cons:

- Slightly longer drying times

Conclusion

Timber materials and wooden worktops have always been at the heart of English Home’s and Kitchens. There is even an old saying “England was built on Oak”. However, just like anything else that is part of the nature, the wood worktops needs to be cared for and maintained on a regular basis in order to preserve their character, liveliness and colors.

There are a wide variety of oils out there that are recommended for treating wooden worktops, however each one has its own application instructions, its own advantages and disadvantages. So, the question remains, how do we choose the right wood worktop oil?

Olive Oil is the most ancient method, but it is definitely not the right choice, if you want to protect your worktop. Teak Oi is a reasonable option which provides sufficient protection, but does not accentuate the colors of the timber, so if you want to show off with your symbolic Solid Oak Kitchen Worktop or characterful Walnut Wooden Worktop, Teak Oil is probably not the right choice for you! Linseed Oil is a very effective timber oil, but Danish Oil does contain Linseed Oil and it is an elaborated version of it. So Danish Oil is one of the most popular choices, as it easily penetrates the pores of the wood, accentuates the colors and grain pattern and most importantly provides a durable protective barrier to the wooden worktop. Nevertheless, it does require multiple coatings and a regular maintenance.

Our favorite choice is Osmo Oil. The oil needs only three coats and it creates the perfect hard-wearing and durable surface, whilst highlighting the unique features of your wooden worktop. The resulting surface is resistant to aggressive stains such as wine and fruit juices and it only requires re-oiling once a year, depending on how active you are in the kitchen. Most importantly, it is extremely easy to apply, just brush in the direction of the grain and disperse equally on the worktop. The only disadvantage that it has it long drying times 6-8 hours for each coat. However, we definitely think that his is a small price to pay for the relief that you will feel once you oil your wooden worktop with Osmo Oil.

Find the Best Oil for Wooden Worktops

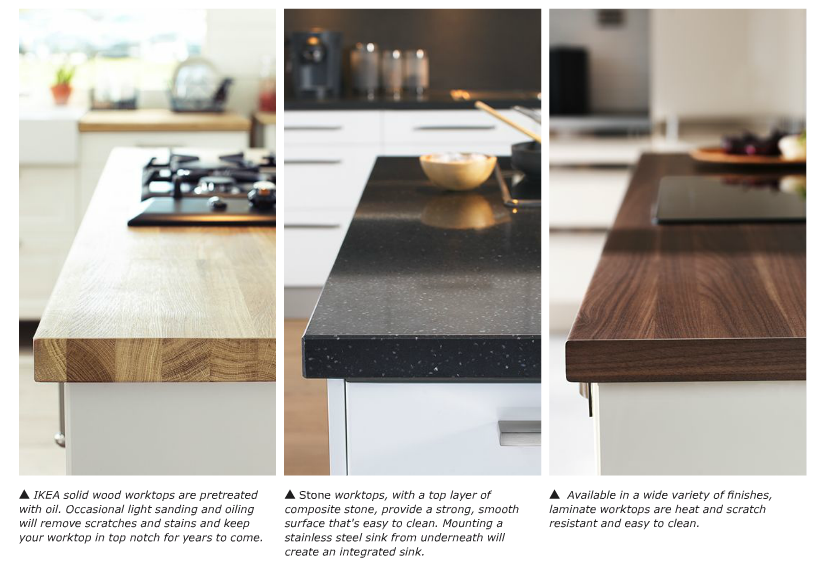

Kitchen worktops come in a huge variety of materials and styles, from man made laminate and composite materials to natural materials such as stone, granite, quartz and wood. All of which give a very specific look and feel and while some worktops can be relatively cheap, others can cost thousands.

One of the more popular kitchen worktop materials, both traditionally and today, is wood. In terms of durability, wood is up there with the best but unlike, stone, slate and granite worktops, it’s less likely to get chipped, lose a corner or suffer from a jagged or damaged edge. Even if it does, repair is usually quicker, easier and cheaper.

When it comes to wooden kitchen worktops, there’s a wide range of woods to choose from with the more common being Oak and Beech, other woods such as Walnut, Iroko and Bamboo are also available as are other more exotic and rare wood types but these usually come at a higher cost.

Wooden Kitchen Worktop Care

Although wood is a great material for kitchen worktops, it does require some care to keep it looking great and functioning well. Wood oils have been used for centuries to protect and preserve wood and although the same is true today, new types and blends of oils are more commonly used.

The pros and cons of wooden kitchen worktops?

By its nature, wood is porous meaning that if left untreated, liquids, juices and bacteria from meats and other sources can seep into the surface grain, discolouring and staining the wood. More importantly, the unsealed wood can create the perfect environment for germs and bacteria to collect and breed.

A common issue with poorly maintained kitchen worktops is black mould around taps and sinks. This is usually caused by water damage and mould spores growing in the surface of the timber, encouraged by warm, damp conditions. Although this sounds serious, as long as the work top hasn’t been varnished, it can usually be remedied by scrubbing the black areas with a

mould and mildew cleaner. This will remove the black staining and kill off the bacteria and spores responsible. In severe cases, a second treatment may be required. Once the wood has been successfully treated and cleaned it’s ready for oiling.

The great news is that wooden worktops can look fabulous and even if they’ve been neglected and abused, left with stains, marks, discolourations and stains, it’s usually a fairly easy process to get them looking amazing again with little more than a light sanding, some white spirit and the all important

worktop oil.

Why Does Oiling Wooden Worktops Work?

Simply speaking, oiling wooden worktops works by filling the surface grain of the timber with natural oils and waxes, that dry and harden in the surface fibres of the timber. This acts as an effective wood preserver and sealer, helping to prevent moisture and bacteria from entering the wood grain.

Wooden Worktop Oil – Old v New

A question that we’re often asked is “Which is the best oil for wooden worktops?” Wood oils such as Tung, Linseed and

Danish Oils have always been used to protect and preserve work surfaces and other types of timber, and are still commonly used today. So why use a modern worktop oil? Which is best? We hear you ask. The difference between traditional wood oils and the newer ranges of wooden worktop oil products comes down to several key differences.

Ease of use – Application and drying times

The number of coats can depend on the type and condition of the wood, many of the traditional oils may require anything from 3 to 7 coats to be effective and with drying times of around 24 hours between coats, oiling a wooden work top could take as long as a week. In comparison, most modern top oils require just 2 thin coats and are dry in 4 to 8 hours, depending on the oil brand and environmental conditions.

Worktop durability

In terms of durability, traditional wood oils tend to require maintenance on a more regular basis as they dissipate in the wood and evaporate from the surface of the worktop more quickly than their modern equivalents. Modern purpose made worktop oils are made from specially formulated blends of waxes and oils, that harden in the surface of the wood, to form a durable, protective barrier.

Oil penetration in the worktop surface

Modern kitchen worktop oils are highly refined and are blended with solvents to thin and aid penetration into the surface of the wooden work top. In many cases, especially on denser woods, traditional wood oils will not penetrate in to the wood as well unless they are first thinned with turps.

It’s true to say however that even with modern top oils some are better suited to specific wood types than others depending on how dense the wood is and how thin the worktop oil is. Some products such as

Manns Premier Top Oil and

Osmo Extra Thin 1101 are especially great for denser timbers such as Beech, Bamboo and Walnut worktops. While

Holzol Worktop Oil is a great all rounder.

The great thing with an oiled wooden worktop is that they look great, are easy to maintain and repair even if they do become stained, scratched or worn looking. For more on the subject, we’ve created a great video that shows how easy it is to apply a solid wood worktop oil.

An additional bonus of top oil products is that because they are completely food and child safe when dry, they’re perfect for rejuvenating and restoring wooden chopping boards and other wooden kitchen utensils.

Top Tip

Applying a top oil to a kitchen worktop will enhance the natural colour, grain and character of the timber. If you’re installing a new or renovating an old worktop by sanding, wipe over a small section with a slightly damp (not wet) cloth or sponge to get a good indication of how the worktop will look when oiled. See our full range of

wooden worktop oils here.

Need help with your wood oil project?

For more information about

wood oils and their uses,

contact our team of resident experts who are always on hand to help with project advice and product recommendations. Alternatively, see our

wood oils FAQ page which covers many of the most commonly asked questions about wood oils.

We love to see before, during and after photos of any wood finishing project. If you would like to share your project pictures with us and our followers, you can either send us some photos or share on our

Facebook,

Twitter,

Pinterest or

Instagram pages.

Other great blogs that talk about wood oils

What are Wood Oils and Where Are They Best Used?

Traditional Wood Oils: 3 of the Best

All about the wooden countertop in the kitchen. 6 secrets of professionals

Natural wood in the kitchen? A wooden countertop is one of the most successful solutions for the kitchen, practical and convenient. You just need to know these 6 professional secrets.

Is there a wooden countertop in the kitchen? We asked real professionals: qualified designers, craftsmen, technologists and wood specialists – those whose opinion can be trusted.

1. Why is a wooden tabletop not scary?

On the one hand, smooth, warm wood with a beautiful natural structure is an excellent material for furniture production. Easy to use, eco-friendly, always fashionable and up-to-date. Moreover, the table top is not an unsupportable wooden cupboard, which is impossible to move. It is not necessary to make all the furniture out of wood, a perfectly reasonable modern solution would be to make only countertops from this material and maybe some other individual parts.

But many people are afraid of how wood can behave, they are afraid of fungus, cracked varnish …

But professionals think otherwise: “Wooden countertops are not a problem if you apply reasonable adequate care to them. There are not many materials used for countertops in non-professional kitchens that are not afraid of any impact and do not require maintenance, – says Andrey Lyamin-Borodin, builder, CEO of PriceRemont online repair ordering service.

So what are we dealing with? Mikhail Vychuzhanin, Wood Finishing Specialist, North House , defines the advantages and disadvantages of wood countertops as follows.

Pluses:

- environmental friendliness of the material;

- beauty and diversity of wood texture;

- unlimited parameters of the product: almost anything and anything can be made from wood;

- is easy to update;

- the ability to perform any milling of the edge of the tabletop.

Cons:

- requires more maintenance;

- will need restoration after some time;

- relative high cost of material and work with it.

2. Which wood to choose for the countertop?

And here is the answer to the question, what types of wood and wood characteristics should be paid attention to.

“When deciding on a wooden countertop in the kitchen, please forget about MDF, chipboard and veneer.

Classic oak or beech: strong and durable woods. Some choose teak and mebrow. More democratic options: pine, walnut, ash, birch. We prefer larch: you will have to pay more, but it will also last longer. A feature of larch is a very high density of wood, annual rings are located along the trunk with small intervals. It easily tolerates mechanical damage and deformation, withstands high compressive and pressure loads. It contains gum – a natural antiseptic that protects against decay and mold damage. Ideal for the kitchen. Larch gives and absorbs moisture when the humidity changes.

The manufacturing method also influences durability. A solid wood table top is more prone to warping than a glued one assembled from several plates. This method increases flexibility and resilience.”

“You should pay attention to such points as: the age of the wood, the method of its extraction, storage conditions, the region where the material was brought from,” adds Mikhail Vychuzhanin . He considers oak to be the best type of wood for making countertops. — The stronger and harder the wood, the longer your countertop will serve you. There are countertops made from solid birch, cherry, walnut.”

The ideal option for protecting a wooden tabletop is a bio-impregnation based on natural vegetable oils and beeswax – that is, oil-wax for wood. Natural oils for wood can make its surface waterproof, which means that wood is not afraid of fungus and mold. By the way, a countertop impregnated with high-quality wax oil becomes resistant to standard kitchen detergents – nothing bad will happen to wood from diluted household chemicals.

4. How practical is a wooden worktop?

How can I save wood besides using wood products?

If you want your countertop to last longer and look better, follow these simple rules: don’t cut anything directly on the wood (perhaps only oak will endure such abuse), don’t test the surface for fire and heat resistance. From very hot objects, the tree can darken, ash is especially sensitive. But if wine or juice is spilled on the surface, it is enough to wipe it with a damp microfiber cloth. Do not use wet rags, this will make the wood swell.

We also do not recommend using aggressive household chemicals to clean the countertop. It happens that drops of such a product fall on the countertop when cleaning the sink or hob.

To the question of choosing a sink – in this case it should be a mortise or, in other words, an invoice. An undermount sink will create a constant effect of water on the edge of the countertop, from which it will inevitably deteriorate. However, lovers of country style or owners of countertops made of especially waterproof wood may not be confused by this.

5. Will this worktop fit my design?

Wooden surfaces in the kitchen are also wide design possibilities, a current trend. Here’s what the designers think about it.

The world is becoming more and more urbanized, and a person is stressed due to the lack of communication with nature.

Since wood is not a moisture-resistant material, the part of the countertop adjacent to the sink can be replaced with an artificial stone surface.

So, a solid wood top with knots, uneven texture, aging effects will suit a rustic or loft style kitchen. But smooth wooden surfaces will look great in modern interiors, high-tech, especially tinted in white, black or graphite – such a tabletop will effectively combine with chrome and glass surfaces. It is worth paying attention to options from glued – perhaps even from different species – wood: the rhythmic pattern of elements can emphasize the beautiful geometry of the room.

6. How to update the wood of the countertop?

Sooner or later, the surface of the wooden worktop will have to be re-oiled. How often should this be done?

It is difficult to name a specific period, a lot depends on specific operating conditions.

A wooden worktop is a great solution for modern kitchens, and there is absolutely no need to be afraid to use wood in the kitchen. A little care for the tree – and your kitchen will delight you for many years!

Wooden countertop in the kitchen: features of protective coatings

Wooden countertop for the rustic kitchen

The smell of strong morning coffee fills the cozy kitchen. You want to be here all the time, inhale the aromas of freshly prepared food – fried meat, mushroom soup, sweet freshly baked muffins. Here you want to meet in the evening, for leisurely conversations after a working day, spend the weekend in pre-dinner chores for the family, or just sit when your family has already fallen asleep with a cup of herbal tea.

Cozy kitchen island with wood top

Contents

- 1 Practicality or durability?

- 2 Oil, wax or varnish?

- 3 Video: Worktop oil on larch

Practicality or durability?

Wooden worktop – one of the most successful solutions for the kitchen, practical and convenient

How to make a worktop practical and durable? Both of these qualities are laid initially, at the stage of choosing a wooden surface.

The worktop must be well sanded and treated with a special compound before use

What should I look for when choosing a kitchen surface made of wood?

- Do not use veneer, MDF, chipboard, only natural wood.

- Matters:

- wood age;

- felling site;

- storage conditions.

- Glued wood products are more flexible and resilient than solid wood counterparts.

- The right finish will protect the wood in the harsh environment of the kitchen. Before covering a wooden countertop with oil or other suitable composition, it is worthwhile to study the available range of coatings, their properties, features. Even better is to test the selected product on a small piece of wood.

- It is necessary to clearly define the methods of surface care, the possibility of recovery in case of damage.

Select hardwoods for wooden worktops

Wooden worktop must be smooth, durable, resistant to moisture, temperature, cuts. A product made from harder rocks will last longer. Classic options for kitchen worktops – oak or beech. More democratic countertops made of ash, pine, walnut, birch.

Since wood is not a moisture-resistant material, the part of the countertop adjacent to the sink can be replaced with an artificial stone surface.

Larch works well. Its dense wood is resistant to mechanical destruction, deformation.

An excellent option for a countertop – an unfinished piece of wood

Advantages of wooden surfaces over other types:

- environmental friendliness;

- beautiful texture;

- variety of colors, shades;

- ease of processing, unlimited possibilities in creating different shapes, neat edge with the possibility of various milling;

- Easy to update and repair.

Glued wooden board top

Minuses to be aware of:

- needs more care than other surfaces

- requires periodic restoration;

- high cost of material, expensive work on its processing.

Wooden countertop must be protected from moisture so that it does not get wet and fungus does not appear .

Solid wood top for dining table

Oil, wax or varnish?

Care and proper use of a wooden countertop will prolong its life

A well-made coating with good compositions will give the wooden countertop a beautiful look, protect it from moisture, aggressive detergents.

To ensure that the countertop lasts longer and maintains its appearance, do not cut anything directly on the wood and do not check the surface for fire and heat resistance

How to cover a wooden tabletop to make it last as long as possible and remain beautiful at the same time?

- Oil, wax.

- Alkyd coatings.

- Waterborne formulations.

Depending on the finish, the same type of wood looks different: polyurethane gel, gloss varnish, wood oil

Ideal impregnation with oil, oil-wax. Oil, saturating the wood structure, gives it water-repellent properties. With high-quality processing with good wax oil, the countertop becomes resistant to household chemicals, detergents, which are often used to wash kitchen utensils.

An ideal option for protecting a wooden tabletop is a bio-impregnation based on natural vegetable oils and beeswax

Apply an oil coating either with a brush or a rag evenly over the entire surface

A special oil designed to impregnate wood that comes into contact with food, ensure environmental friendliness.

Wood worktop oils can be vegetable, synthetic or mineral

You can apply colored azure, stain, other water-dispersion coatings, followed by varnishing. The properties of the varnish used, its resistance to moisture, and the multi-layer coating are important.

Varnish treatment is better, because the wood is covered with a protective layer, which is much stronger than oil protection. Do not mix alkyd and acrylic coatings. Before covering the countertop with the main composition, it is important to choose the appropriate primer.

Preparing the wooden table for varnishing

You can use a primer that matches the natural color of the wood, or a colored primer that matches the color of the varnish with which the wood will be coated

Tip!

For maximum durability, the coating must be renewed one year after application. The tool for “getting used” to the surface takes time at different temperature conditions. When exposed to external conditions, microcracks appear on the surface of the coatings, which are visually indistinguishable.

Sanding the surface and applying a layer of varnish along the grain of the wood

Beech wood before and after processing: on the left – raw beech, in the center – after treatment with white oil, on the right – oil varnish

The quality of the coating can be tested in the following way: apply several drops of water and see how quickly they are absorbed. A good coating has excellent water-repellent properties.

Water exposure can only be short-term, otherwise the wood will have to be sanded and waxed again

It is important to take into account the drying time of the compositions, it can vary from several hours to several days. Natural oils, acrylic mixtures have a long drying period or accumulate strength gradually over time, so it is important to limit the use of the countertop during the drying period.

It is impossible to protect wood from scratches, mechanical impacts with paints or oils, so there is only one way out – to treat wooden countertops with the utmost care.

Wooden worktop – the perfect solution for modern kitchens

The slight casualness of the wooden surface will give the kitchen … humanity. Isn’t that what we value the most? Humanity… Kitchen? Why not?

A place for wood can be found in the kitchen in any style, it is only important to approach the matter correctly

Wooden countertop in the kitchen, it is a beautiful and high-quality material that will decorate your kitchen

Video: Oil for worktops on larch

Previous

OtherHow to make your own modern style bedspread

Next

OtherHow to crochet a bedspread

Using oil and wax on wood countertops

|

Wooden countertops, especially kitchen countertops, need protection: they are most often exposed to moisture, heat, direct sunlight. There are two main ways to protect wood, which not only protect it from harmful external influences, but also give it a beautiful appearance – varnishing and oil impregnation. What is more suitable for countertops and how to properly protect the tree? Let’s figure it out. Wood damage factorsIf the room is at the same time high humidity, poor ventilation and a comfortable temperature for the growth of bacteria (depending on the type – from 15 to 65 ° C) and moldy fungi, any wooden surface is at risk. So can a kitchen cutting board turn black Do not forget – and this applies mainly to the kitchen – that aggressive solutions (acids and alkalis) change the chemical composition of wood and thereby worsen its appearance and strength characteristics. Another factor of damage is direct sunlight. But here the situation is ambiguous: on the one hand, ultraviolet has a pronounced bactericidal effect. But in addition to the destruction of bacteria, it almost instantly begins to destroy the unprotected surface of the tree. It becomes silver-gray in color and loses its strength. Finally, do not forget about possible (and in the case of a cutting board – inevitable) mechanical damage. They put a hot frying pan, scratched it with a knife – they ruined the countertop or board. It may seem subjective, but we are for butter. Yes, the lacquer looks beautiful, dries quickly and is inexpensive. But the lacquer coating has drawbacks, which, in the case of countertops and especially cutting boards, will emphasize the advantages of the oil:

On the lacquer, any defects are immediately visible Types of oils by dryingOil dries more slowly than varnish because it penetrates into the wood and the varnish polymerizes on its surface. But oils are different: depending on the composition, completely drying and non-drying oils are isolated. Linseed oil coating is most often used for the initial impregnation of wood. When tung oil is added to it, the drying process is accelerated. In this case, tung oil perfectly replaces metal desiccants (a substance that is added to the oil for faster drying). G-Nature Natural Worktop Oil uses this combination. Rosin is also added to it as an excellent antiseptic and wax to give the surface a matte sheen after polishing. Oil handlingSurface preparationWorktop oil is applied to the surface, which must be previously cleaned of dirt and grease. The oil must not be used on damp, wet (more than 12% according to DIN EN 13183-2) and frozen materials. To evenly distribute and absorb the oil, it is necessary to sand the wood with abrasives – first coarser, gradually moving to finer ones. For final sanding, it is sufficient to use sandpaper P180-220, although you can also take fine-grained abrasive P240-P2500. After grinding with each of the abrasives, the surface must be cleaned. Application ofFor a sanded surface, the average oil consumption is:

Stir the oil for 3-5 minutes before use. Apply an even layer with a slight excess of oil to the surface – a brush, roller or soft cloth is suitable for this. Apply oil with a soft brush or soft cloth Both oil application and drying must be carried out at a temperature of at least +16 °C. Drying and maintenance of countertopsAt +20°C and 55% relative humidity, the surface dries to the touch in 12-16 hours. Complete drying under these conditions occurs after 7-10 days. During this period, it is important to prevent water, dirt and direct sunlight from getting on the countertop. At low temperatures and high humidity, or when applying an excessive amount of product, the drying time will increase. Wooden countertops and kitchen boards need to be updated once every 3-6 months, because they are subjected to constant mechanical stress, systematic exposure to moisture. |

- Oil

Please enable JavaScript to view the comments powered by Disqus.comments powered by Disqus

How to cover a wooden countertop for the kitchen: tips + photos from professionals

The choice of countertops is one of the most important issues in the arrangement of the kitchen, which must be resolved first of all. After all, this is a work area. It is noteworthy that every day a lot of strength tests fall on her. For example, hot dishes, cutting products, splashes of boiling water, fat, spilled liquids… That is, the main part of the load falls on the work surface.

And in this article we will tell you in detail how to cover a wooden tabletop so that it retains its original appearance and performance for as long as possible.

Wood is the material preferred by the majority.

Don’t plan to spend money on a solid wood kitchen top, but want a quality and environmentally friendly product? Pay attention to the product line from the Kedr brand.

With over 180 decors to choose from, you can choose the right one for every interior concept. It contains products that are indistinguishable from real wood in appearance. And the E1 emission class guarantees the environmental safety of the material under any operating conditions.

Top Cedar 7053/FL* Taxus

Benefits of wooden worktops

The worktop is a must-have in the kitchen. Of course, the beauty, durability and service life of the entire headset depend on its quality. It is easy to guess that this is why customers of elite kitchens, first of all, pay attention to wooden countertops.

Photo from source: ivd.ruTop top Cedar 2075/FL Oak Kera

Wood is nobility, sophistication and environmental friendliness.

Also, the advantages of solid wood surfaces include:

Safety both during operation and disposal;

Amazing look of natural wood texture;

pleasant and warm to the touch;

Can be molded into different shapes, i.e. no design restrictions;

always stay in trend;

Can be used in all interior concepts, i.e. in all styles from classic to high-tech.

Varieties of wooden countertops

The durability of products made of solid wood directly depends on the method of production, the type of wood.

The hardest and therefore most expensive species are beech and oak.

Photo from source: fotostrana.ruTabletop Cedar 3829/Nw Bunratty Oak

Products made of birch, ash, walnut, and pine will be cheaper.

Top Cedar 8215/12D Bourbon Pine

Manufacturers especially prefer larch due to its durability.

Be aware that solid wood products may warp over time. Glued wood is assembled from several plates. It is maximally elastic, flexible, resistant to moisture, sudden changes in temperature.

Worktop Requirements

There are two things to keep in mind when considering how to finish your wood kitchen worktop.

The first is durability.

Secondly, practicality.

These are the two main requirements for a kitchen top.

GOOD WOODEN WORKTOPS SHOULD ALSO:

not react to aggressive household chemicals;

do not fade in the sun, do not change its color;

water-repellent;

harmonize with the overall design style;

be heat resistant so that hot food does not leave marks or damage;

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·hare of easy maintenance – due to the fact that bacteria and germs accumulate in the recesses of loose surfaces.

How to coat a wooden worktop?

In order for the working area to serve you as long as possible, provide it with reliability, heat resistance, strength, and water repellency. To make it so will help the coating, which is chosen correctly.

Oil

Photo from the source: master-kraski.ru

Impregnation with oil is the best method for protecting solid wood products.

First of all, it helps the wood to repel water, due to the formation of a barrier film that prevents the structure from getting wet.

Please note that this coverage will require periodic renewal.

Compounds are available in different colors. Therefore, your possibilities for decorative design are almost limitless.

The base may be mineral, vegetable or synthetic. But, of course, industrial tung, citrus and linseed oils will provide the most reliable protection.

Divided into drying:

Partially – the wood is impregnated to deep layers. To remove the top layer, use a mechanical method;

Completely – does not wash off with water, forms a hard top layer.

It is best to apply oil formulations in at least two coats. Before applying a new one, the previous one must dry well.

How to oil a wooden worktop?

To make your wooden worktop last as long as possible, treat it properly. Everything is important here – the means, the thoroughness of surface preparation, application, drying.

Photo from the source: instagram.com

STEP 1: Primary surface treatment

The first step is to remove traces of grease and various contaminants. After that, the tree is dried. To better absorb the oil, the material is polished. First use coarse, and then fine abrasives.

The wood is cleaned after every abrasive treatment. If deep scratches appear on the kitchen top, they are sealed with putty. Wax-based restoration kits are best suited for this.

STEP 2: Preparing the product for application

Everything is simple here. To prepare the oil for use, stir it for five minutes immediately before application.

Attention! Quality is the main thing when choosing an oil. Don’t skimp on it. A good surface protector will help to avoid damage from moisture, mechanical stress, make the countertop shiny and refresh its appearance.

STEP 3: Apply

Apply the oil compound to the work surface with a cloth or brush.

Attention! Choose a fabric that does not leave lint.

Allow the first coat to dry for at least 12 hours. After that, it will be possible to apply the next, and, similarly to the same principle, proceed further.

The number of coats you need is directly related to how you apply the oil. For example, if with a cloth, then you will need to apply up to four layers, and if you use a brush, then only two.

Step 4: Dry

It may take from several hours to several days before complete drying, nothing can be said for sure. However, information regarding the timing should be indicated on the packaging.

Oils with a natural base, as well as mixtures containing acrylic, dry the longest.

About the benefits of oil coating

Enhances natural color;

does not peel;

· Does not flow under the influence of high temperatures;

prevents the formation of fungus;

in contact with food, not capable of causing harm to health;

hides small scratches, scuffs.

Wax

Wax is a natural, environmentally friendly material. But in addition to the water-repellent coating, it also creates protection against scratches and scuffs. Can withstand common kitchen cleaners.

Photo from the source: ufa-les.ru

Attention! The wax wears out fairly quickly, so you’ll need to polish and refinish more often than you would with oil. Before each update, the old layer will have to be cleaned.

Varnish

Photo from the source: kitchen-eco.ru

Varnish allows you to leave a beautiful natural wood pattern, gives a more saturated color.

What kind of lacquer should be used on a wooden worktop?

Photo from source: tiu.ru

Acrylic or polyurethane varnish is recommended. The area treated with them will withstand cold, hot dishes without any problems. It also creates a reliable protection against pollution.

To remove the lacquer coating, the surface will need to be sanded.

Lacquering process

It takes place in several stages:

REMOVING THE OLD COATING

Clean the surface to a “clean” wood. This can be done in three ways:

Chemical – Uses a remover that is applied with a roller or brush for ten minutes. The old layer of varnish is removed with a rag;

mechanical – carried out with different-grained skins or grinders;

Heat cleaning – for this use a building hair dryer.

REMOVING DUST FROM THE SURFACE

It is best to use a vacuum cleaner for this. At the same time, pay special attention to the corners of the table, other places where dirt could accumulate during the grinding process.

FILLING SCRATCHES

If there are scratches, fill them with putty. The best option is the one based on wax.

STAIN

Apply a small amount of stain. Do not allow stains, streaks, bumps to occur during the work.

Staining is a wood processing process. It prevents mold and wood decay.

DRY

Dry after application. Please note that the drying time of the varnish depends on its type, that is, it can be from 18 to 36 hours.

GRINDING

Do an intermediate sanding with sandpaper to remove small unevenness, if any.

Liquid glass

Photo from the source: derevoblog.ru

This is an epoxy resin – a transparent polymer that contains sodium and potassium silicates.

Soda glass is best suited for decorating wooden worktops.

COATING ADVANTAGES

retains original shade;

Will not peel off;

Will not crack, wear resistant;

Will not be spoiled by spilling hot coffee;

Easy and simple maintenance

Dilution of water glass is carried out with ordinary tap water. To make the coating look like real glass, the wood is cleaned and well sanded.

Liquid glass is diluted with ordinary tap water. To make the coating look like real glass, the wood is cleaned and well sanded.

The composition is applied in a spiral, leveled with a spatula towards the edges from the center. It is important to have time to give the desired shape before the liquid glass hardens.

Dye is added to create a colored coating.

Self-adhesive film

By far the easiest way to cover. Allows you to update a kitchen top that has grown old.

Photo from the source: mebpilot.ru

Before proceeding with the finishing, clean the treated area well with sandpaper.

Attention! Clean thoroughly. Avoid the formation of air bubbles under the film!

In stores you can find a huge range of self-adhesive films with a variety of designs – imitations of stones, solid wood of any species, plain, with a pattern.

The surface with such a film is easily cleaned from dirt, can serve for a long time without wear, fading.

Soft glass

Photo from the source: spkubani.club

You can cover with oilcloth or tablecloth, but they wear out very quickly.

Transparent PVC film is an adequate alternative. It is also called soft glass. Withstands household chemicals, relatively high temperatures, is not saturated with water, does not undergo deformation. No scratches remain.

Excellent for surfaces made of wood, chipboard, MDF, glass, metal, artificial stone, agglomerate.

What is the best way to coat a wooden worktop?

When choosing a flooring, you need to rely on your desires, as well as on the design of the room as a whole.

Photo from the source: reciclaredecorar.com Countertop Cedar 3198/Mw Tree Rhodes

Do you work with wood yourself? Do you want to make a reconstruction of an old tabletop or create it from scratch yourself? Then choose compositions of oil and wax. They will protect the array from moisture, scratches, and the negative effects of high temperatures. Lacquers are less popular at the moment.

Need a quick worktop restoration? An excellent option would be to use a self-adhesive film, the color and design of which can be chosen so that the surface is in perfect harmony with the headset, the interior as a whole.

If you want to experiment, create a masterpiece with your own hands, try liquid glass. They can fill not only a tree, but also add a herbarium, shells, sea pebbles, branches to the composition.

Photo from the source: art-build-msk.ru

Can chipboard replace natural wood?

Chipboard (chipboard) is a composite material that contains chips mixed with resin.

If you do not see the point in spending money on a solid wood kitchen top, but want an aesthetic product with good performance, pay attention to the following options: – a thin layer made of natural wood. A protective layer of varnish is applied on top.

Visually indistinguishable from solid wood worktops. Among the shortcomings – the average level of resistance to chemicals and scratches.

Melamine lining

Photo from the source: sdelai-lestnicu.ru

In this case, chipboard is finished with kraft paper, which is impregnated and coated with melamine resin. Solvent and moisture resistant.

Can have any pattern, including the texture of natural wood.

Plastic laminated

HPL laminated. It is resistant to UV rays, mechanical stress, moisture, food acids and any household chemicals. Differ in durability and simplicity of leaving. These are beautiful, versatile pieces.

Gives the greatest scope in terms of design. On the market you can find decors with a very high quality imitation of wood or stone.

If you are looking for a high-quality worktop with an affordable price tag, then pay attention to chipboard with HPL lamination.

Photorealistic imitation of the array will please the eye, reliability and ease of maintenance will save you from additional expenses and worries, and a high level of environmental friendliness will allow you not to worry about the health of the family.

We have embodied these advantages in the line of countertops “Kedr”. Our task is to provide the client with a high-quality, aesthetic and durable product at an affordable price. Get more information on the official product resource.

Top Cedar 690/P Indian wood

Conclusion

We hope our recommendations will help you choose the best material and finish for your wood worktop. Or will you settle for a democratic alternative, such as veneered/laminated chipboard?

In any case, we want to make the right choice, which will satisfy all requests and not hit the wallet.

See you in new articles!

Repair and savings

What is the best way to coat a wooden worktop?

Protection of wooden kitchen worktops from external influences

In the vast majority of cases, kitchen worktops are wooden surfaces, since wood is a common and relatively affordable option. Environmental friendliness and good appearance are its advantages. But at the same time, one should not forget the susceptibility to destruction due to numerous external influences. However, this problem is solvable, since covering the countertop with protective components will help make the wood strong and durable, and improve its appearance even more.

Advantages of wood in the manufacture of kitchen furniture and countertops in particular

- Wooden countertops, unlike plastic ones, are environmentally friendly;

- Unlike countertops made of natural stone, wooden counterparts are cheaper;

- Naturalness in design.

Attractive appearance;

- Ease of restoration.

Disadvantages of wood as a component of kitchen furniture

The kitchen is characterized by strong temperature fluctuations and high humidity, which has a very serious effect on wood, unlike the same stone and especially high-quality plastic At the same time, if we talk about the worktop, it should be noted also exposure to fats, detergents, knives and the like, found in the kitchen. The above-mentioned plastic and natural stone again win in this regard.

Finally, a quality worktop made from good wood species can be significantly more expensive than plastic, although cheaper than natural stone. And don’t forget the risk of fire.

Oil is the best way to protect wood

It doesn’t matter whether it’s a kitchen countertop or other wood furniture, varnishing is becoming less and less common these days. The reason is that the varnish is very environmentally friendly due to the large number of synthetic components.

Modern oil compositions are deprived of all these shortcomings. By applying them to the sanded raw wood surface, we create a layer on it that is distinguished by excellent resistance to water and other influences. At the same time, the texture of the wood does not change, but the oil itself does not have unpleasant odors, unlike varnishes. It is worth noting here that there are both natural oils and synthetic, as well as mineral.

All wood oils are divided into two types – those that dry immediately, and those that dry partially. The former on their own represent a very serious protection for a wooden countertop, creating a durable solid layer on its surface. The latter impregnate wood to a certain depth. In this case, the top layer of oils can be removed, and wax can be applied on top, for example.

What are the benefits of oil in countertop protection?

Wood worktop oiling process

Before starting work, make sure the wood is clean and free of old paint residue. In this case, the surface must be carefully leveled and sanded. The recesses can be patched.

Important! To apply the layer, use a brush or soft cloth. The main thing is that the latter does not leave traces.

Using a brush, two coats are sufficient.

Coating a wooden countertop with paint

If oil, for one reason or another, does not suit you very much, then paint can become an option for solving the problem. In the event that we are talking about an old board, then many of the actions here are repeated with the above. We also need to first clean up old layers of varnish or paint, then clean the surface of dirt and dust, sand it and smooth out irregularities, if any. After priming, several layers of alkyd paint are applied to the wood.

Worktop film

Another way to protect the wood surface of your worktop is to apply self-adhesive film to it. Such a surface has a number of advantages:

- The film does not let water through, and also endures the effects of various liquids and household chemicals;

- The design of the film is varied.

The material can imitate both different surfaces, as well as have a pattern or pattern;

- If you want to update the appearance, you can remove the old film and mount a new one.

As a disadvantage, we can recall that this element is still artificial, which eliminates all the advantages of wood described above. In addition, when applying the film, you must be careful, since the slightest mistake can lead to wrinkles and other defects that spoil the appearance of the wood.

How to prevent damage to your worktop

Even with the relative fragility of wood, its proper use can significantly extend its life and maintain its original appearance. All that is needed for this is to follow a few simple rules.

Do not clean the surface of the worktop with non-aggressive chemicals. Try to choose the right cleaner and do not delay cleaning.

Even though the worktop is still a work surface, it is still best to use an appropriate cutting board for cutting.

- To increase the protective qualities, as in the case of a countertop, a wooden cutting board can be coated with oil or antibacterial impregnation;

- A simple remedy – ordinary sunflower or olive oil. To maintain the protective effect, it is recommended to apply at least once a month;

- Remember to wash your board thoroughly with hot water after each use and dry it well. As a preventive measure, you can wipe the board with hydrogen peroxide or vinegar. If there is serious contamination, use detergents.

If the worktop still fails to protect

Most often, damage to wood appears in the form of chips or dents. In this case, the wood often rots, and these areas also need to be removed, which again leads to the formation of voids that need to be filled. In this case, several steps must be taken:

- Thoroughly clean the surface of the wood, and also process it with sandpaper or a grinder;

- Place a mixture of sawdust and putty or polyvinyl acetate adhesive into the recesses.

Then place under the press and let dry for several days;

- Before painting or other surface treatment, it is important that the patched areas have a level appearance.

The nuances of choosing a wooden worktop

So that all the above problems occur as rarely as possible, and repair work is not required. When choosing a wooden worktop for the kitchen, there are a number of nuances to consider.

Material. If we talk about wood, then the best options are oak, teak, walnut and beech and others. These breeds are strong and durable. But they are also the most expensive. In the case of choosing other options, pine is the best. It contains resins that protect the wood from decay.

Manufacturing method. One-piece countertops (array), which were mentioned above, not everyone can afford. Therefore, in the selection process, people often give options to glued models. The latter, especially if they consist of different types of wood, can combine the strength, visual appeal and positive features of all varieties of their constituent wood.

How to coat a wooden worktop?

The kitchen is the heart of our home, a place where everyone visits at least once a day, and for many families it is also a place where the whole family gathers every day, cozy communication, heartfelt conversations. For many housewives, the kitchen is the place where they spend a huge part of their time, and the convenience and beauty of this place largely determines whether working in the kitchen will be a heavy duty or a joyful creative process.

When buying a kitchen, many people spend a lot of money on the kitchen itself and its equipment, but often do not pay due attention to such an important detail as the worktop.

That is why for a long time even ardent adherents of natural materials in the decoration of the house had no access to such luxury as countertops made of natural wood. After all, when choosing a wooden countertop, many questions arose. First of all, how to properly protect a wooden countertop for a long time? How to cover a wooden countertop and how to care for it. Is it possible, if necessary, to update the appearance of the countertop, to remove traces of damage? In addition, the composition of the countertop coating is of particular importance, because it must be harmless to food that will be in direct contact with the countertop.

Now, to the great joy of those who want to get a wooden worktop, there is an ideal solution to all problems. Mir Pola offers the most environmentally friendly Top Oil with hard wax, developed specifically for wooden furniture and countertops, from OSMO, a German manufacturer of natural wood preservatives.

+ For furniture and countertops (including kitchen worktops)

+ Leaves wood pores open

+ Water repellent

+ Does not crack, peel or flake

Consumption: 1 liter per 12 m2 in two coats

processing furniture and kitchen worktops. The wood remains natural, while emphasizing the natural color and structure of the wood.

The treated surface acquires wear resistance, dirt and water repellency. Any stains are easily removed from it. Areas subject to heavier loads are easy to renew. To do this, it is necessary to clean the damaged area from dirt and apply a new layer of countertop oil, while no differences from the previously treated surface will be noticeable. No sanding required!

Furniture and countertop oils are based on natural vegetable oils and waxes. Thanks to this, the pores of the wood remain open, and the coating is not subject to cracking, peeling and peeling.

The treated surface is resistant to cleaning agents, drink stains, water and complies with DIN 68861-1C.

Colorless countertop oil does not require special skills to apply.

Enhance the gloss of the treated surface by additional polishing.

Oil base

A special combination of natural oils and vegetable waxes. Deep penetration into the wood structure and protection against drying out. Vegetable oils do not interfere with the natural moisture exchange of wood, thereby reducing the risk of swelling and shrinkage.

Health & Environment

Osmo countertop oils are free from biocides and preservatives that can adversely affect human health. Dried oil does not pose a danger to humans, animals and plants and complies with the German standard “Safety in case of possible contact with skin and saliva”.

Osmo’s strategy is to manufacture and sell products that are safe both during production and in use.

Use