Cavity wall insulation bath: Cavity wall insulation | Bath and North East Somerset Council

Cavity wall insulation | Bath and North East Somerset Council

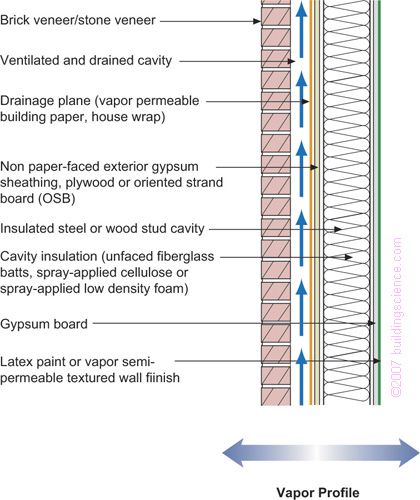

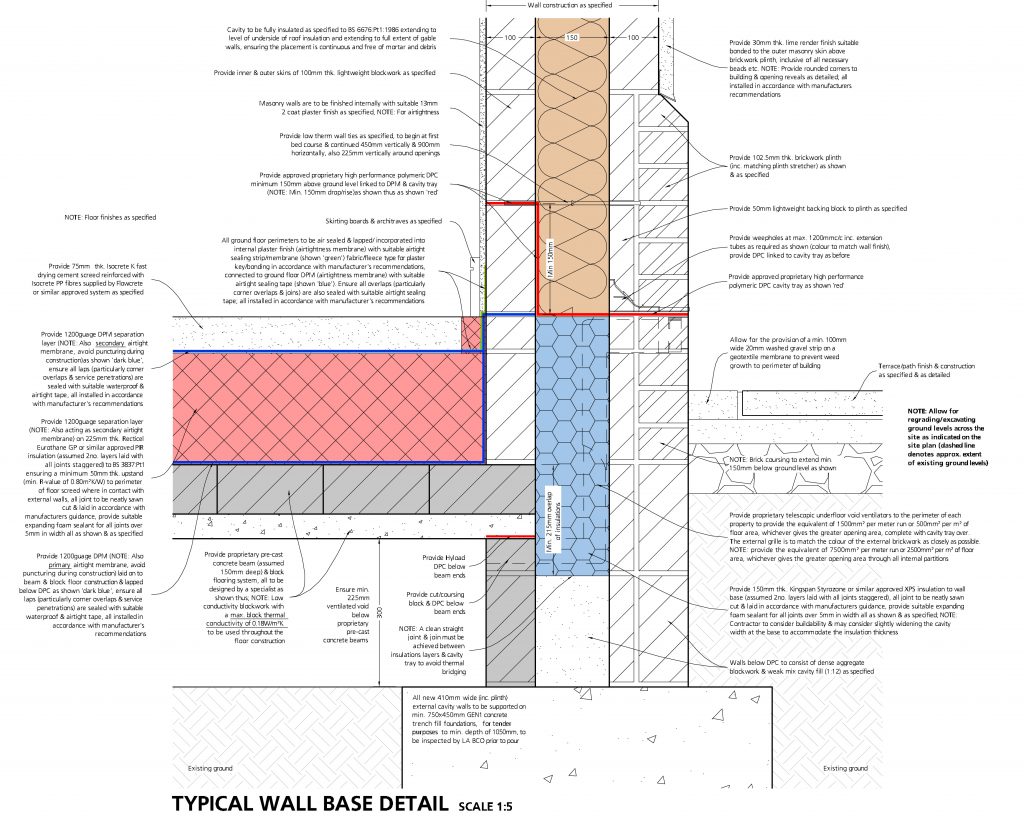

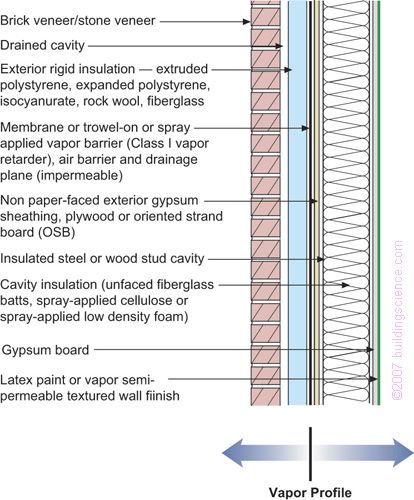

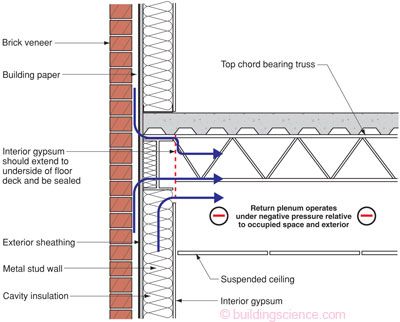

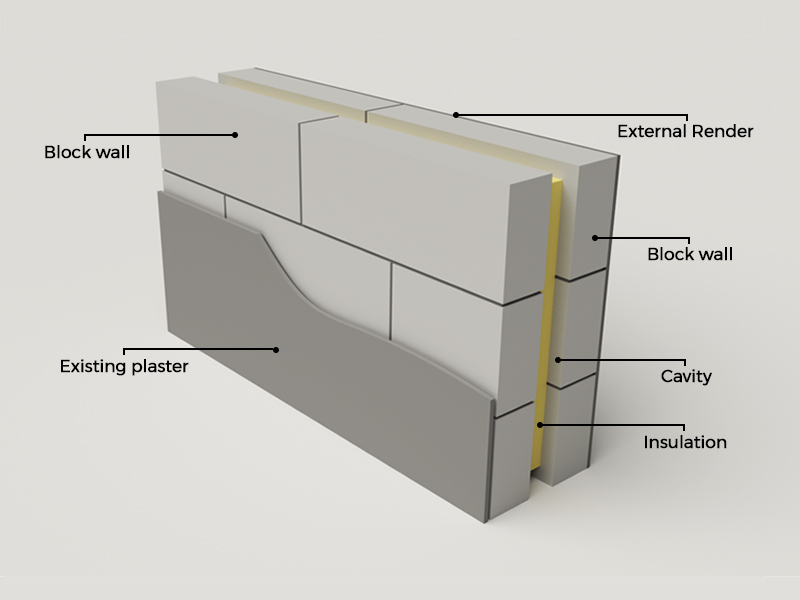

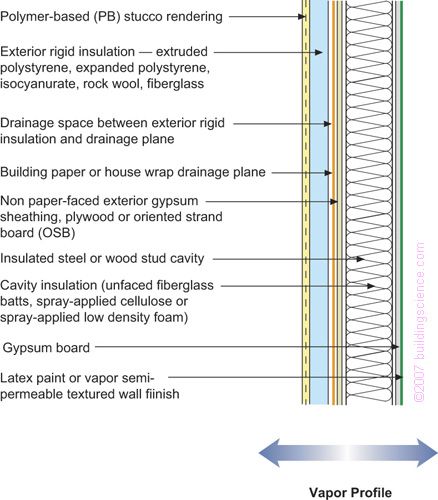

The majority of buildings constructed in the 20th century have external walls constructed of two layers, the outer being a weathering skin and the inner one usually structural. Space between the layers is a cavity used to drain any moisture which passes though the outer layer preventing it from reaching the inside.

These cavity walls are usually quite thin and, being made of slender components, normally have low thermal performance.

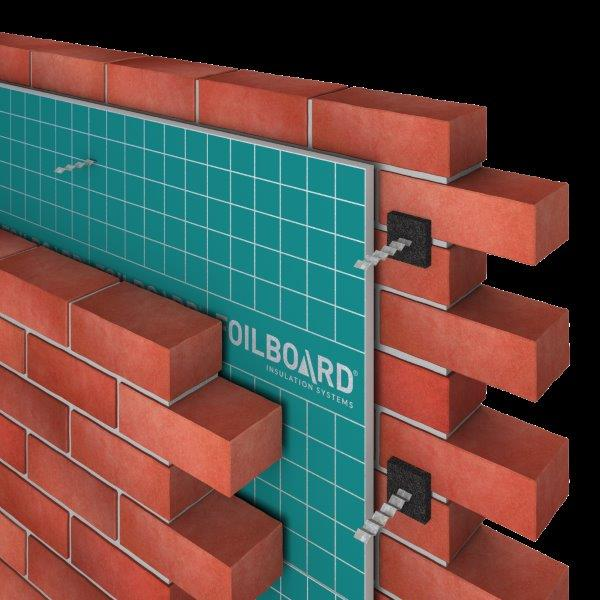

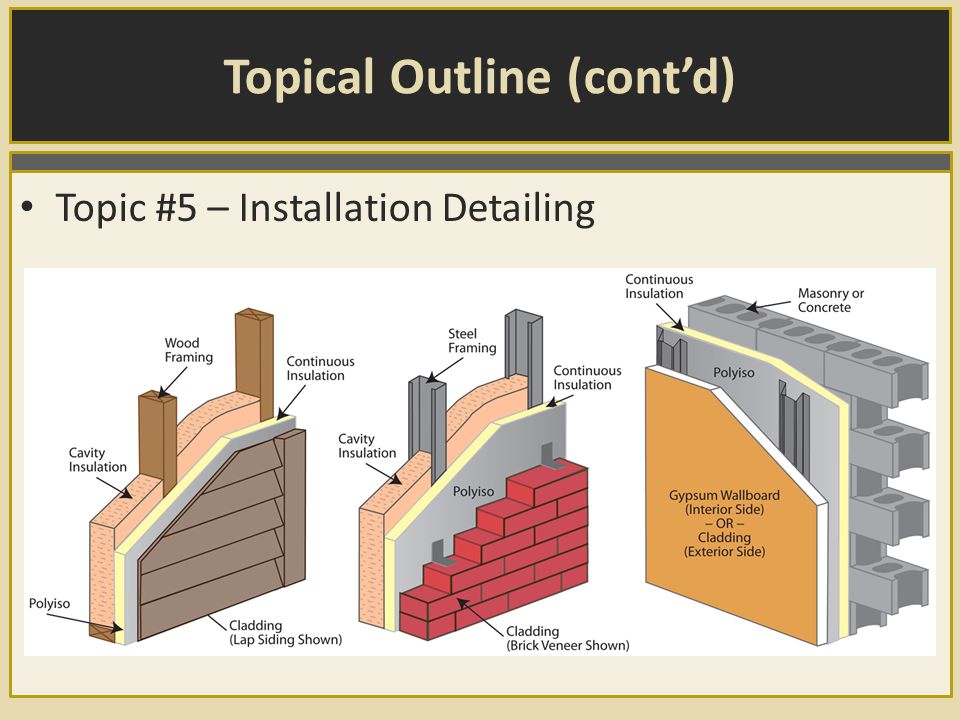

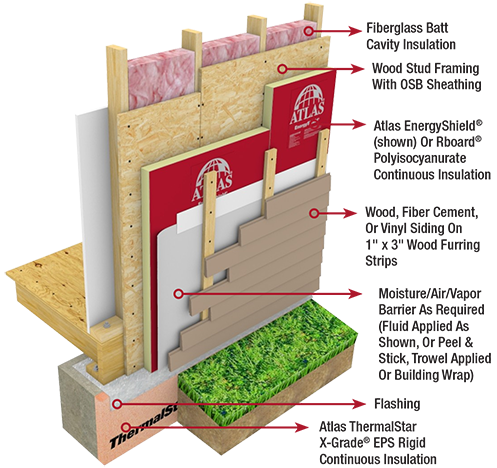

Cavity wall insulation is a method of improving the building envelope by insulating the void between the skins of a cavity wall.

A number of methods are available which involve an insulant being injected into the void. These insulants vary in their thermal efficiency, moisture resistance, and integrity (ability to support themselves). The more commonly used insulation types are expanded polystyrene spheres and blown fibres.

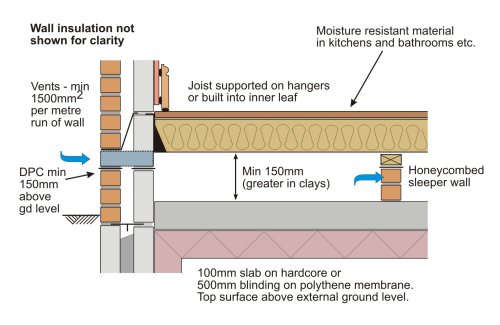

The insulation is normally fitted over 1 to 2 days with holes drilled at intervals on the facade to allow the insulation to be injected. Particular care must be taken at openings, perimeter of the cavities, ventilation routes, and damp-courses to ensure the building can function as designed. A detailed survey will need to be undertaken by the installer to assess the suitability of the building for the insulation type being proposed.

Some highly exposed walls may not be suitable for cavity wall insulation.

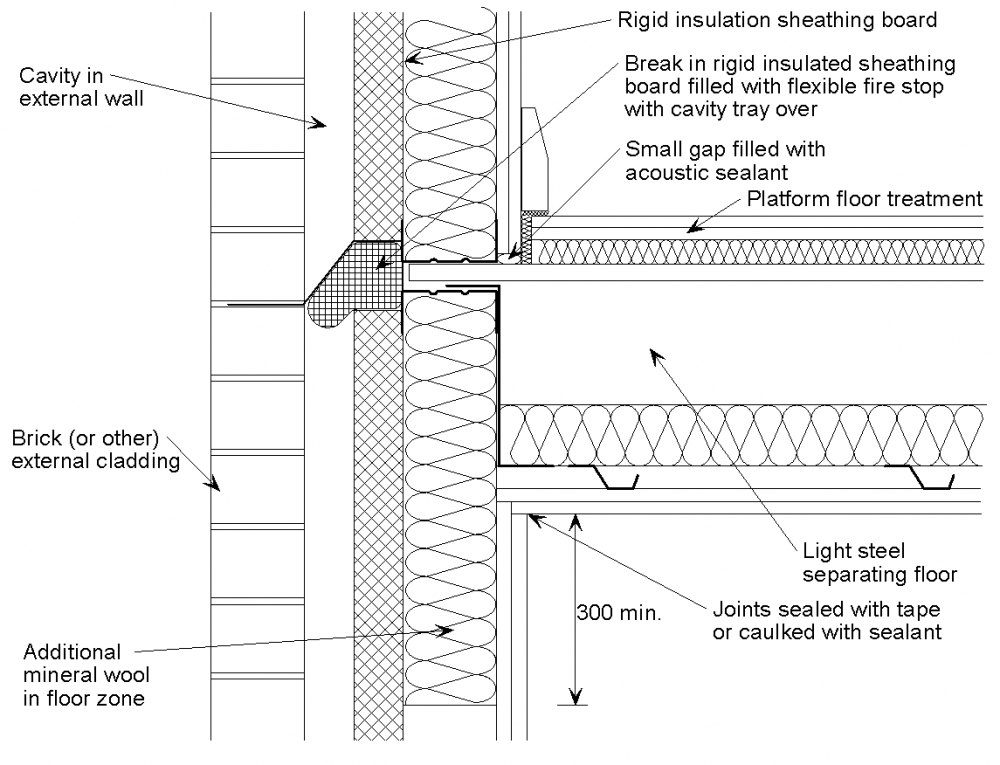

In later modern homes the cavity may already be partially filled with an insulation board, and here retrofitting top-up insulation can be difficult as the void can be quite narrow.

This insulation can be fitted without disruption, making it a suitable choice for many.

The external walls of any building are normally the largest proportion of its envelope and so offer the greatest potential for heat loss. This element is therefore very important to improve.

The effectiveness of the insulation will vary with the type of insulation chosen, size of cavity, and proportion of wall to say windows, roof, etc.

For most, an improvement in wall performance of around 35% will be possible.

You should use recycled materials wherever possible.

This cost will vary with the type of insulation, thickness of cavity and complexity of building – e.g. amount of scaffold required. Typical payback periods for cavity wall insulation are medium term, between 5-8 years. According to data from BEIS, the estimated cost of cavity wall insulation is between £22 and £26 per m2.

Some grants and financial assistance are available. Refer to the Energy Savings Trust, your utility company, or our Energy at Home website for more information.

Listed Building Consent is required for cavity wall insulation within heritage assets.

Pre-1920 houses are more likely to have solid walls. A solid wall has no cavity. Each wall is a single solid wall, usually made of brick or stone. It is unlikely that cavity wall insulation is a relevant retrofitting measure for consideration in most heritage assets or buildings of a traditional construction.

We support the use of cavity wall insulation where appropriate.

In the light of the Climate Emergency, we will generally permit and encourage alterations on listed buildings, with special regard to the the following:

- Preserving the building, its setting or any features of special architectural or historic interest which it possesses

- Preserving or enhancing the character of a conservation area

- Respecting the significance of any non-designated heritage asset

Cavity Wall Insulation & Removal Bath

Propoint UK are domestic and commercial Cavity Wall Insulation & Removal contractors that are trading standards approved and all work guaranteed. We’re Cavity Wall Insulation experts, this includes inspection services, removal and installation.

We have many trusted teams and offer our services throughout the UK including the Bath area.

Some unscrupulous tradesmen and companies are attempting to trade off our good name. Please take care not to be deceived by companies providing inferior workmanship. We are the original Propoint UK, established over 20 years ago.

Our Bath Cavity Wall Insulation and Removal Experts

We have an experienced Cavity Wall Insulation expert team for Bath. We offer Cavity Wall Insulation and Removal and almost all types of property restoration services for big business properties and residential properties in and around the Bath region.

Our professional Bath group of hired craftsmen have a real knowledge and dedication for the practice of Cavity Wall Insulation Inspection, Removal and Installation.

Cavity Wall Insulation Surveyor Bath

We are experiencing a large number of clients that have Penetrating Damp. This might be as a result of saturated cavity wall insulation bridging the gap. Cavity insulation that has failed and fallen to the bottom of the cavity can be misdiagnosed as a DPC issue.

If your building has damp issues, in order to confirm the cause of the issue, we highly advise you to have an survey report carried out. This is a non-intrusive process where a inspector will drill a small hole, and then would check the cavity with small cameras. They will then discover the condition of the insulation.

Afterwards, a detailed survey report will be written up, detailing exactly what has been done within the investigation, the survey results, and our unbiased recommendations to resolve the problem.

Insulation Removal Service

Propoint UK do cavity wall extractions throughout the UK.

Using specialist tools and machinery, our Bath Cavity Wall Insulation removal team will extract all insulation that is causing issues or may require removal for some structural repairs. We will extract your insulation without disturbing the buildings structure or exterior. Propoint UK have many years of experience in extracting insulation from both domestic and commercial properties across Bath.

Cavity Wall Insulation Installation

As well as extraction, we carry out CWI installations in and around Bath. We are known within the industry for providing a high quality service and installing high performance, injected blown bead insulation systems.

Our blown bead insulation provides one of the best cavity wall insulating properties, perfect for domestic, commercial and industrial use. Providing a full cavity fill leaving no cold spots, no waste and it’s easy to install.

About Bath

Bath may refer to:

Propoint-UK carry out cavity wall insulation instalations throughout the UK and we are known in the industry for providing a briliant service and installing high performance, injected blown bead insulation systems.

To find out more or get a competitive quote, contact us today:

Contact Us

Blown Bead Insulation

- more efficient than rock and glass wool insulation

- less drill holes required

- reduces heat loss

- annual savings of up to £275 on heating bills

- full grant funding available

- consistent density with constant thermal protection

- fire resistant and waterproof

- bonded finish ensures no damp or thermal bridging

- suitable for driving rain and bad weather areas

- fast and clean installation

Need Cavity Wall Insulation & Removal in Bath? Call Now 0800 240 4634

Do-it-yourself warming of the walls of the bath from the inside

The technology of warming the bath involves three successive stages: warming the ceiling, then the walls and, last but not least, the floor.

Contents of the article

- 1 Scheme of the “pie” of thermal insulation of the bath walls from the inside

- 2 Features of thermal insulation of walls made of different materials

- 3 Sauna insulation materials

- 3.1 Classic mineral wool

- 3.2 New generation mineral insulation

- 3.3 Glass, peat and paper insulation

- 3.4 Modern foil insulation

9 0021

- 4 Conclusions

Schematic of the wall insulation pie saunas from the inside

Before starting work, be sure to eliminate all defects: close up and insulate the cracks, treat the walls with flame retardants and antiseptics, if necessary, check the tightness of the joints, etc. After completion of the preparatory work, you can proceed with the installation of thermal insulation.

The pie itself generally looks like this:

- the wall on which the bars are stuffed;

- heat insulator laid between the bars;

- vapor barrier;

- lathing batten that holds materials and serves to mount the trim.

Sauna wall insulation scheme

Step 1. A crate of bars is fixed on the walls into which a heat insulator is tightly inserted. The thickness of the bars should correspond to the thickness of the thermal insulation. A vapor barrier is attached to the bars, which, as a rule, use aluminum foil. After the foil, a crate is attached under the lining with a thickness of 20-30 mm, and then the walls are sheathed with a lining.

Main conclusions:

- It is not necessary to leave a gap between the insulation and aluminum foil in the bath;

- It is desirable to leave a gap between the aluminum foil (or other foil material) and the lining so that the condensate can flow down freely.

Otherwise, the lining will rot very quickly.

Place heat insulator tightly between the bars. The thickness of the insulation corresponds to the thickness of the bars

It is also necessary to determine the direction in which the bars will be nailed to the wall. They can be nailed vertically and horizontally. And there is constant debate about how best to do it. Some builders claim that with a horizontal location of the heat insulator, and hence the bars, there is less heat loss. Their opponents say that ventilation is better with a vertical arrangement. More importantly, everyone chooses for himself, as well as whether or not the bars need to be treated with antiseptics and fire retardants.

Tip! It makes sense to think not about how to fix the bars, but first of all about how the lining will be attached: horizontally or vertically. It is more practical to mount the lining horizontally. In this case, the condensate, which will inevitably form on the vapor barrier, will be able to flow down unhindered, so the crate under the lining will be mounted vertically.

The step of filling the bars, under the insulation, is determined by the width of the selected heat insulator: the distance between the bars should be approximately 1 cm less than the actual width of the insulation (in this case, the insulation will fit snugly against the bars).

Tip! Be sure to measure the width of the insulation before attaching the battens. Do not trust the data on the packaging: firstly, there may be factory deviations, and secondly, during storage and transportation, the edges may wrinkle, thereby reducing the actual width. Any gap and loosely fitting heat insulator is a place where cold will penetrate and condensation will form. These areas are also called cold bridges.

Step 2. Insulation is laid tightly, without gaps, with little effort between the stuffed bars. With the right distance between the bars, the heat insulator holds itself well, but to be sure, you can fix it with hot-dip galvanized or stainless steel screws and washers of large diameter (read this article about the choice of fastening materials for the bath).

If a foil heat insulator is chosen, to ensure tightness, close each connection with a patch of aluminum tape, and on top you need to fix another piece of adhesive-backed foil – tightness is very important: most heat insulators lose their properties in the presence of moisture. For example, the thermal conductivity of wet basalt wool is much greater than dry. For this reason, the insulation must not be allowed to get wet.

In this case, it is also necessary to carefully seal the joints of the foil thermal insulation and the bars: they must be glued with the same foil tape, ensuring at least 5 cm overhangs both on the insulation and on the bar.

Joints must be glued with aluminum tape

For a steam room, foil is considered the best material to prevent moisture from penetrating into the insulation. It not only retains moisture well, but also reflects heat back into the room, greatly reducing its loss. If you choose such a material, the time required to heat the room will significantly decrease, the costs of maintaining the required temperature will decrease, the stove will work in a more gentle mode, which means it will last longer.

For steam rooms, it is recommended to use foil or foil materials as a vapor barrier.

In other rooms, any other material suitable for performance characteristics can be laid.

Strips of the selected material are laid so that they overlap by at least 5 cm. All joints are additionally carefully glued with foil tape, which is sold in the same place as the vapor barrier. Attach it to the bars with staples and a construction stapler. To maintain tightness and prevent steam from entering the thermal insulation, it is advisable to glue the joints with the same foil tape.

The video below shows how insulation is installed in a Finnish sauna and covered with aluminum foil.

When the ceiling is insulated, there must be a “sunset” of the heat and vapor barrier on the walls. When installing wall insulation, put it on top of the wall “pie”, and then carefully seal the joints (use foil tape again).

Step 3. After the installation of the “pie” is completed, a crate of planks is stuffed onto the protruding bars. It will hold the materials, and will also serve as the basis for attaching the interior trim.

This is how the wall may look after all the work is completed: 1 – insulation, 2 – vapor barrier, 3 – lining

Features of wall insulation made of different materials

The technology and sequence of insulation layers remains almost unchanged for different rooms and types of buildings. Only some parameters can be changed. So, for example, for a steam room, the thickness of the insulation is recommended twice as much as for other rooms : it is here that it is very important to retain heat for the maximum amount of time.

The thickness of the insulation also differs for buildings made of different materials. A log bath itself holds heat well, and when finishing all rooms except the steam room, you can do without insulation at all, or choose a material of small thickness – if the winters in your region are harsh.

The video below explains why there is no need to additionally insulate the walls of a log bath (the plot of the program “Estate”).

Insulation of brick sauna walls from the inside is practically no different, except for the methods of fastening: it is more difficult to drive nails into a brick wall, you can use dowels. You can use galvanized profiles instead of wooden bars, but when buying them, pay attention to whether they are suitable for use in rooms with high humidity. And with the choice of sizes it is much more difficult here: there are not so many standard sizes, and metal can become a conductor of cold. Insulation of the brick walls of the bath from the inside implies a greater thickness of thermal insulation than in a log bath: minimum – 10 cm , but this parameter depends on many factors: wall thickness, external insulation, region, etc.

Foam block does not hold fasteners well

The fastening of the crate must be done so that the main load falls on the floor, and not on the walls. To do this, you can make U-shaped structures that are attached to the floor and ceiling, just fix their position in the walls with a pair of dowels.

Tip! To further reduce the load on foam concrete walls, you can not fasten the planks tightly to the wall, but make clamps from pieces of galvanized steel that will only hold the slats in a vertical state. The entire load will be on the floor.

Lay the insulation tightly between the slats, and fix it so that it does not fall, you can use a thread and a stapler (shoot the thread to the slats).

The last step in the insulation of the bath walls from foam blocks is the installation of a crate for interior decoration. This is a similar frame of U-shaped sections, the load from which is distributed mainly on the floor. This frame is attached to the first one in several places to the bars.

This is just one solution that allows you to insulate the walls of the bath from foam blocks, but it is simple in execution and quite reliable.

Materials for sauna insulation

The choice of material for insulation is a rather complicated process: it is necessary to take into account not only the technical characteristics of heaters, but also their environmental friendliness, harmlessness, and fire safety. It is especially problematic to correctly select a heater for a steam room, since it has not only high humidity, but also high temperature, which causes the release of toxic substances from some types of heaters.

Classical mineral wool

Not so long ago, almost everyone advised using mineral wool to insulate the bath, but recent studies have shown that in production, a composition containing phenol-formaldehyde resins is used as a binder. They have a harmful effect on a person, are a carcinogen, which in itself is unacceptable, and in a bath or sauna with its high temperature, it is generally very dangerous. Yes, the certificates indicate that the release of these substances does not exceed the threshold, but do you need it?

Even Rockwool or TechnoNIKOL stone wool, any other mineral wool from well-known or not manufacturers, emits phenol-formaldehyde substances. In general, according to physicians and experts, any mineral wool is harmful to health. In this regard, the question arises: “what is the best way to insulate the bath?”. There are several materials about which there are no negative opinions. At least for now…

Next generation mineral insulation

URSA PUREONE is touted as a new generation of mineral insulation.

URSA PUREONE material is one of the harmless insulation materials

URSA PUREONE safety is confirmed by the EcoStandard group (classified as M1 material by Eurofins, EUCEB certified).

URSA PUREONE environmental certification

Glass, peat and paper insulation

FOAMGLAS® foam glass is foamed glass. It does not burn, does not lose its properties over time, is stable in shape, environmentally friendly and safe. Its only drawback: the high price and rather large weight.

Foam glass

There are also peat-based insulation – peat blocks . Crushed peat is soaked with water, filler is added – straw, sawdust, etc., blocks are formed from the resulting mushy mass, which are used as heat and sound insulators. The resulting material not only reduces heat loss, but is also a “breathable” material – it absorbs well and also releases moisture well, has a bacteriostatic effect, does not burn or rot.

Peat block is not the most popular material yet

Despite all the positive qualities, peat blocks are not the most common material, and there are few manufacturers of this material. The most famous is the GeoKar enterprise from Tver. If all the declared qualities are confirmed, then this is a good alternative to mineral wool.

There is also such a heat insulator as ecowool . This is a cellulose substance, mostly consisting of recycled newspapers, to which safe (according to the manufacturers) fire retardants – boric acid and borax salts – are added. Everything would be fine, but this material strongly absorbs moisture, and is not suitable for thermal insulation of the bath.

Fibreboard – are made from crushed wood chips, but using a different technology than the well-known fiberboard – without chemical binders. The chips are ground, diluted with water, distributed over the grid. The mass simply dries, after which it is cut into canvases.

Among the safe heaters, one can also name natural heaters made of flax, wool, moss, reeds. Use as a warming material and sawdust, reeds and straw. But all these substances are combustible, and without treatment with special compounds they cannot be used to warm the bath.

Modern foil insulation

In this article, we couldn’t help but tell you what modern insulation materials Finns use when building saunas. Hot Finnish guys use SPU Sauna-Satu insulation boards, specially designed for wall and ceiling insulation in the sauna.

SPU Sauna Satu boards are made of polyurethane foam and coated on both sides with an aluminum laminate.

SPU Sauna-Satu

SPU Sauna Satu can be attached to walls even without battens. The process of attaching the slabs to stone walls and wooden ceiling lathing is shown in the video.

At the moment, SPU Sauna Satu slabs can be attributed to the most suitable heaters for baths and saunas.

Conclusions

The main problems of sauna insulation are connected with steam room insulation, as it has not only very high humidity, but also high temperature. Under the influence of high temperature, many heaters begin to release toxic substances that can harm human health. For this reason, it is necessary to carefully choose mineral wool insulation, as many of them contain phenol-formaldehyde resins that act as a binder.

Styrofoam and expanded polystyrene should not be used as insulation, which, when heated to 60 degrees Celsius, begin to release toxic substances.

In fairness, it should be noted that many natural materials that are harmless at normal temperatures, when heated, can release substances that can harm human health.

At the moment, we can recommend the foil insulation SPU Sauna-Satu, which is specially designed for the insulation of sauna walls and ceilings.

How to insulate the ceiling in the bath with your own hands: step by step instructions

Considering the high humidity and temperature, thermal insulation of the ceiling in the bath requires a special approach.

Why insulate the ceiling in a bathhouse

A bathhouse with a cold roof requires mandatory ceiling insulation, which is caused by two reasons at once: maintain the required temperature. This will lead to an overrun of firewood, and in addition, the bath will become uncomfortable. You will need to regularly go out into the dressing room and throw firewood.

Also, abundant condensation will cause additional moisture to the ceiling. In such conditions, wood significantly reduces the service life.

Also, abundant condensation will cause additional moisture to the ceiling. In such conditions, wood significantly reduces the service life. Types of sauna heaters

Several types of heaters are suitable for thermal insulation of the sauna ceiling:

- Mineral wool. One of the most popular materials, produced in slabs or rolls, has a fibrous structure. The chaotic arrangement of the fibers provides a large number of air pores, which is why mineral wool is one of the most energy-efficient heaters. Mineral wool is not interesting for rodents, does not burn and is not afraid of high temperatures, which is especially important for the bath ceiling. However, mineral wool is a hygroscopic material that needs high-quality protection from getting wet. When saturated with moisture, the insulation loses a significant part of its performance properties.

- Foil insulation. There are 2 versions of foil insulation: foil mineral wool insulation and foil polymer insulation.

The foil qualitatively reflects IR rays and does not require the arrangement of a vapor barrier, as it does not allow moisture to pass through. However, it is not recommended to use foil insulation based on polymeric materials for the ceiling of the bath. With strong heating, it tends to twist and deform, which opens up access to the cold roof and part of the warm air freely penetrates through the gaps formed.

- Expanded clay. Easy to install, environmentally friendly insulation. It is a small hollow clay pebbles. It has a number of advantages, including low cost, resistance to fire, long service life, unattractiveness to rodents. However, expanded clay, like mineral wool, is afraid of dampness, therefore, it needs high-quality vapor and waterproofing. Also, expanded clay has a fairly high coefficient of thermal conductivity, therefore, to insulate the ceiling of the bath, it is necessary to pour about 40-50 cm of material.

- Penoizol. Universal insulation in the form of polymer foam.

It is applied with special equipment in a thin layer and quickly foams, forming a cellular urea foam. In addition to the ceiling, it can be used for the roof of the bath. This is a relatively inexpensive, durable, energy-efficient insulation. The main drawback is the impossibility of insulating the ceiling in the bath with your own hands. To perform the work, it is necessary either to hire specialists involved in this type of thermal insulation, or to rent expensive equipment.

- Ecowool. Environmentally friendly material, 80% recycled paper, 20% non-volatile flame retardants such as boric acid. It is a very loose, lightweight composition with high thermal insulation characteristics and a long service life. The main disadvantage is the need to use special equipment for spraying, since the manual method of thermal insulation of the bath ceiling does not give the desired effect.

- A mixture of clay and sawdust. Environmentally friendly and very cheap, but labor-intensive material.

To insulate the bath ceiling, 5 parts of sawdust are mixed with one part of clay and applied to the base with a layer of 10 cm.

How to insulate the ceiling of a sauna from the outside with your own hands

The easiest and most common way to insulate a sauna with a cold roof is from the outside from the attic. This method facilitates installation and provides a higher quality of thermal insulation. We will consider the procedure for insulating the roof with mineral wool, as this is the most popular option. Mineral wool insulation is distinguished by good value for money, long service life and easy installation. To insulate the ceiling in the mineral wool bath, it is not necessary to involve special builders.

At the initial stage, the order of work is different for the steam room and dressing room (rest room). A vapor barrier membrane is immediately laid in the dressing room, on top of which a heater is mounted. The steam room is a warmer room where a large amount of steam is expected to form.

In other respects, the insulation of the ceiling in the sauna with mineral wool does not differ from the type of rooms and requires the following order: The direction of the lag must be chosen in such a way as to provide the least sag. If there is an interior partition, it is better to lean the logs on it, placing it across the wall, and not along it. When using mineral wool for the roof, the distance between the lags should be 1-2 cm less than the width of the insulation so that it sits tightly. This will prevent the formation of cold bridges in the future, when the tree dries out a little.

Along the perimeter of the ceiling of the bath, the membrane is glued to double-sided tape and additionally fixed to the wall with reinforced tape. All joints are also glued with reinforced tape. During installation, pay attention to the surface of the membrane, according to the manufacturer’s instructions. Usually it is turned with a certain side to the insulation.

Along the perimeter of the ceiling of the bath, the membrane is glued to double-sided tape and additionally fixed to the wall with reinforced tape. All joints are also glued with reinforced tape. During installation, pay attention to the surface of the membrane, according to the manufacturer’s instructions. Usually it is turned with a certain side to the insulation.

How to insulate from the inside

Insulating the bath ceiling from the inside implies the creation of exactly the same heat-insulating cake, but the order of work is different. For proper insulation of the ceiling in the bath, you need:

- Lay waterproofing foil.

- Mount the joists.

- Lay insulation with additional fixation with string, dowel or other fixing materials.

- Lay vapor barrier film.

- Nail the guide rails along the joists.

- Trim the ceiling of the bath with clapboard.

Insulation of the ceiling and roof of the sauna with mineral wool

By insulating the ceiling with mineral wool in compliance with the above technologies, you get a durable, high-quality thermal insulation that you can do yourself.

Otherwise, the lining will rot very quickly.

Otherwise, the lining will rot very quickly.

The foil qualitatively reflects IR rays and does not require the arrangement of a vapor barrier, as it does not allow moisture to pass through. However, it is not recommended to use foil insulation based on polymeric materials for the ceiling of the bath. With strong heating, it tends to twist and deform, which opens up access to the cold roof and part of the warm air freely penetrates through the gaps formed.

The foil qualitatively reflects IR rays and does not require the arrangement of a vapor barrier, as it does not allow moisture to pass through. However, it is not recommended to use foil insulation based on polymeric materials for the ceiling of the bath. With strong heating, it tends to twist and deform, which opens up access to the cold roof and part of the warm air freely penetrates through the gaps formed.  It is applied with special equipment in a thin layer and quickly foams, forming a cellular urea foam. In addition to the ceiling, it can be used for the roof of the bath. This is a relatively inexpensive, durable, energy-efficient insulation. The main drawback is the impossibility of insulating the ceiling in the bath with your own hands. To perform the work, it is necessary either to hire specialists involved in this type of thermal insulation, or to rent expensive equipment.

It is applied with special equipment in a thin layer and quickly foams, forming a cellular urea foam. In addition to the ceiling, it can be used for the roof of the bath. This is a relatively inexpensive, durable, energy-efficient insulation. The main drawback is the impossibility of insulating the ceiling in the bath with your own hands. To perform the work, it is necessary either to hire specialists involved in this type of thermal insulation, or to rent expensive equipment.  To insulate the bath ceiling, 5 parts of sawdust are mixed with one part of clay and applied to the base with a layer of 10 cm.

To insulate the bath ceiling, 5 parts of sawdust are mixed with one part of clay and applied to the base with a layer of 10 cm.